ST. CLAIR SHORES, MICHIGAN (February 6, 2025) – The STAHLS’ Heat Press Transformation series continues to spotlight businesses leveraging heat printing innovation to enhance efficiency and scale operations.

In Episode 5 of the series, viewers step inside USColorworks, a large contract print shop just outside Charlotte, North Carolina, to see firsthand how high-volume apparel production thrives with heat press technology and automation. Led by Dave Conner from STAHLS’ Transfer Express and industry expert Marshall Atkinson, this episode provides an in-depth look at how USColorworks processes an astounding 25,000–30,000 garments daily, including 3,000 on-demand pieces, with a streamlined and highly automated workflow made possible by STAHLS’ Fulfill Engine.

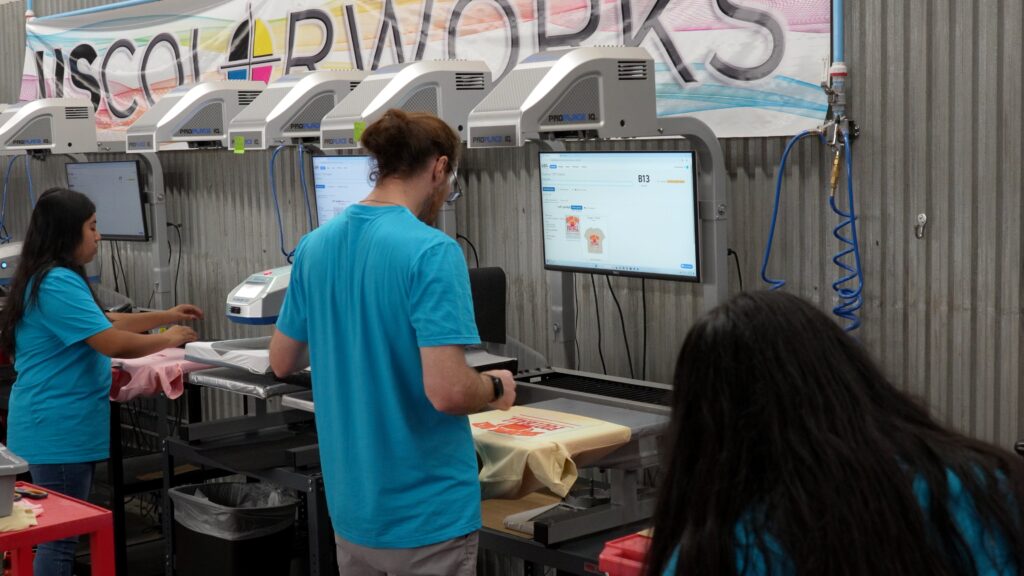

USColorworks operates with 160 employees and integrates a diverse range of decoration methods, including screen printing, embroidery, direct-to-garment (DTG), and direct-to-film (DTF) printing. The episode explores how heat press technology plays a vital role in their high-volume efficiency, enabling quick turnaround times without sacrificing quality, including the ability to accept order quantities of all sizes, including individual orders.

One of the biggest game-changers in their operation is the STAHLS’ Fulfill Engine software, which simplifies order management and accelerates operator training, ensuring seamless production and fulfillment. STAHLS’ Fulfill Engine even allows their high-volume shop to accept order quantities as little as one without any disruption to the large-scale schedule.

“Nobody wants to touch that PO for one piece,” says Rodney McDonald, Co-Owner USColorworks. “STAHLS’ Fulfill Engine gives you the opportunity to produce that single piece order and ship to your customer direct. It’s the easy button for print on-demand.”

The Heat Press Transformation series is dedicated to helping decorators of all sizes discover strategies for success in an evolving industry. Whether you’re a small business or a large-scale producer, Episode 5 offers invaluable insights on scaling production, leveraging automation, and optimizing heat press technology for maximum efficiency. STAHLS’ Fulfill Engine simplifies fulfillment so any business can scale with less.

To learn more about the heat printing solutions available through STAHLS’, visit stahls.com/home. To learn more about STAHLS’ Fulfill Engine or schedule a demo, visit stahls.com/fulfill-engine. Watch Episode 5 of the Heat Press Transformation episode featuring USColorworks or view the full series on the STAHLS’ TV YouTube channel.

STAHLS’ is a long-time member and supporter of NSGA.

Topics

USColorworks Dave Conner Rodney McDonald Decoration Marshall Atkinson Heat Press STAHLS Sporting Goods

Back

to News

Back

to News